Over the past few weeks, approximately 45,000 kilograms of reinforcing steel have been intricately woven together between the two northernmost metro tracks. This ingenious weaving forms the reinforcement for the final roof section of the Brittenpassage, which is by no means the largest or heaviest of the seven sections. Tomorrow will see the Nieuw-Zuid Construction Consortium (Mobilis, Boskalis and Van Gelder) pour 240 cubic metres of concrete into the formwork (wooden mould) that has been placed around the reinforcement cage, after which the sheet will weigh around 650,000 kg once it has hardened. By way of comparison: the most southerly roof section weighs arount 650,000 kg once it is hardened. However, this modest roof section turns out to be one of the most complicated to build, explains Peter de Jong, site supervisor at the BCNZ Construction Consortium. ‘We’re building this roof section on our smallest construction site, where most of the work is taking place. On both sides, we’re working just a few metres away from the metro tracks. Just delivering materials presents a difficult puzzle: we have a tiny construction entrance leading from busy Parnassusweg.’

Moving work in summer 2024

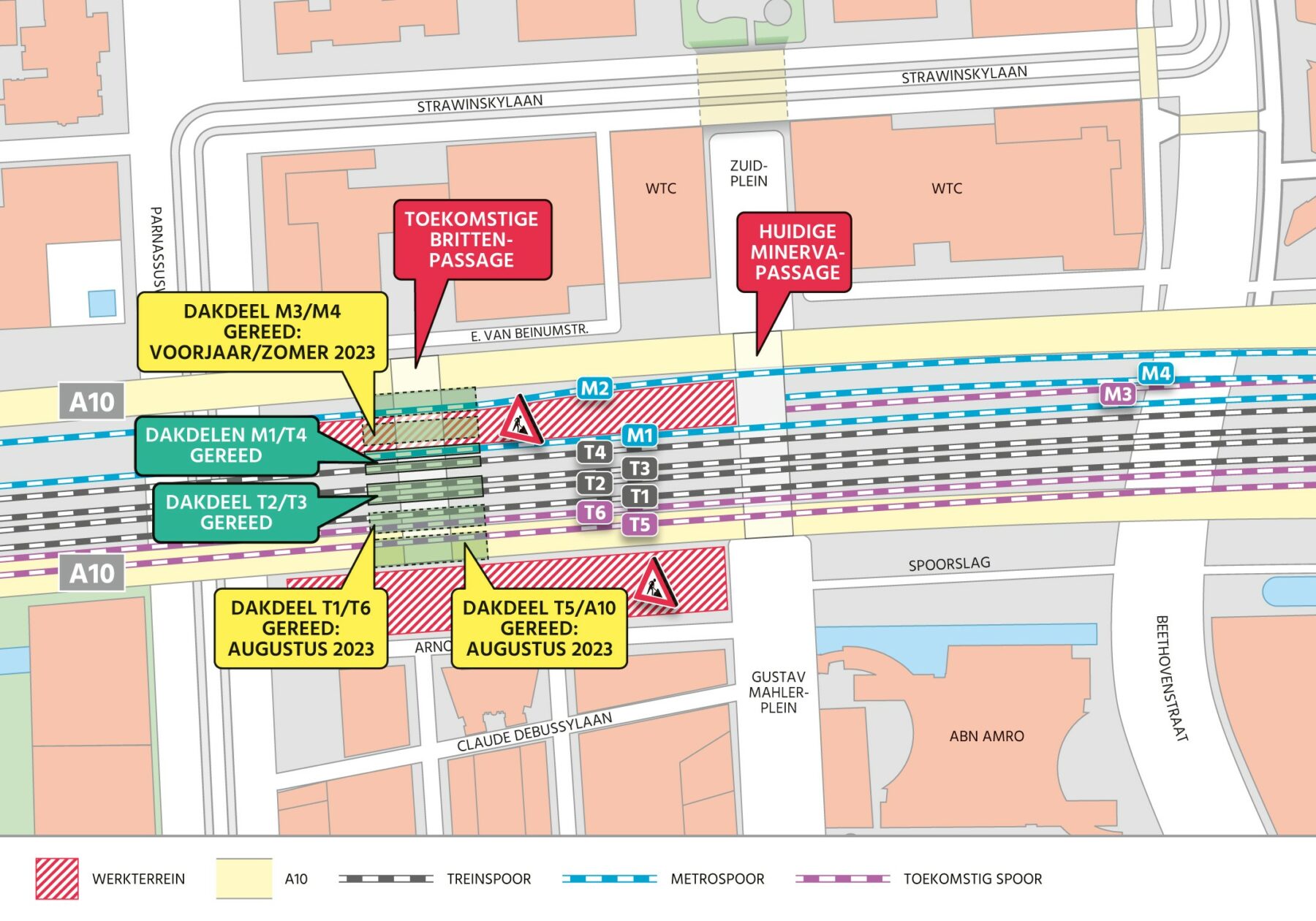

It’s been four years already since we moved the first section of the gigantic concrete roof for the new Brittenpassage into its position. It was a spectacular operation, which required the removal – also for the very first time – of a section of the A10 Zuid, tracks and platforms. Afterwards, we carefully reconstructed everything, and in the years that followed, we repeated this (quite complex) feat multiple times. That includes last summer, when we moved two huge roof sections from Arnold Schönberglaan on the south side of the station underneath a train track and the A10. Five of the seven roof sections for the Brittenpassage are now in their final positions. The six has already been pre-built, but is currently being used as a construction road to our work site. Number seven will be slided under the northernmost metro track (M2, see map) in the summer of 2024.

18,000 kg of post-tensioning steel

Six silver tubes have been pulled through the mass of reinforcement rods. These are known as conduit pipes through which cables have been drawn. When the concrete of the roof section has been poured and hardened, these cables will be tensioned. This will enable the concrete slab to bear a greater load later on. De Jong explains: ‘In order to do this effectively, the conduit pipes need to be positioned with millimetre precision. We’ve pulled 36 post-tension cables through each pipr. And remember: these cables have a combined weight of 18,000 kg already. We can tension the cables two weeks after pouring the concrete. This essentially causes the roof section to slightly arch upward. Once the metro travels over it, the arch flattens, and the roof section becomes level again. If you don’t do this, you run the risk of cracks in the concrete later on because it may sag a bit.’

Northern metro track supported by coffer dam

The reinforcement cage for the roof section and the formwork around it (a type of massive mould into which the concrete is poured) were pre-built on runners, with a large scaffold structure underneath. This is required to bridge the difference in height between the northern and southern side. After all, by the end of August we were already starting to dig the Brittenpassage. ‘We started on the south side. We’ve now reached a reasonable depth, so we had to start digging on the north side, as otherwise the clearance from the ground would be too much’, explains De Jong. Since there was still no roof section or foundation underneath the most northerly metro track (it will be moved into position in the summer of 2024), it was not possible just to dig here. This is why, earlier this year, we installed dozens of sheet piles in the ground on both sides of this metro track. Underneath the track, the sheet piles are connected together by large pins (anchors), creating a coffer dam structure. The track can remain sturdily supported on this structure while we continue to dig on both sides of the sheet piles.

Foundation piles and abutments

When the concrete for the seventh roof section has been poured and dried, it will be power-floated and the post-tension cables will be tensioned. In the summer of 2024, we will spend several weeks removing part of the most northerly metro track and the coffer dam. This will give us time to install foundation piles into the ground here, onto which we will build abutments, which will ultimately support the roof section. We are also building some interim supports and runners. We will then push the most northerly roof section around 9 m to the north so that it comes to rest on top of the new abutments and supports. Later on this year, we will also we will also move the sixth roof section, currently still in use as a construction road to our site between the metro tracks, several metres into its final position. After that, excavation work can start on the north side. The Brittenpassage is set to open in 2027 at the latest..

Give your opinion